The near-net-zero ‘Las Casitas’ are small rental houses at an event venue at the historic town of Round Top. Read more about the case here!

CyBe Construction offers transparent insights into our work. On this page, you can explore our various case studies and success stories, and learn more about each project. We have finished countless cases, often of variable types. We’re sure that there is a project that is comparable with your case. Find out what makes our unique process efficient and sustainable here!

The near-net-zero ‘Las Casitas’ are small rental houses at an event venue at the historic town of Round Top. Read more about the case here!

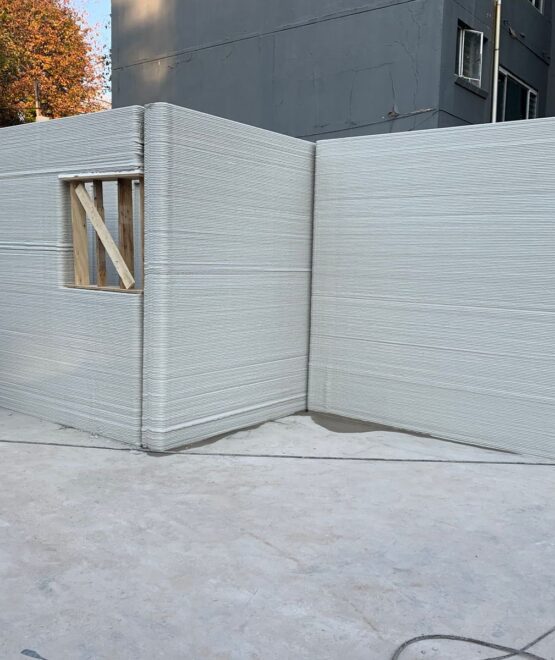

The Paremoremo House in Auckland, New Zealand, is currently regarded as the biggest 3D printed house in the Southern Hemisphere. Read more about the case here!

These Living Seawalls made in collaboration with Kind Designs, Miami, mimic coral reefs and mangroves, hosting biodiversity and improving the quality of water. Additionally, they are embedded with sensors to collect 15 parameters of essential data.

CyBe Construction offers 3D concrete printing solutions globally. On this page, we will focus on what benefits we have to offer for 3dcp housing in Florida specifically.

Creators Forest Lake in Hamilton, New Zealand, makes history as the Southern Hemisphere’s first 3D printed commercial building. The building serves as an early childhood center, offering a safe, high-quality environment for children to run around in.

The Huia house in Manukau Harbour, New Zealand, is the world’s first passive solar house using 3D concrete printed walls. Passive solar houses use energy from the sun for heating and lighting. 3D printed walls excel in maintaining a constant temperature, making them perfect from passive solar homes.

The University of Johannesburg House enters the history books as South Africa’s first-ever 3D printed building. The building was a project by UJ’s Department of Architecture and Design and Department of Science and Innovation, aimed at investigating whether 3D concrete printing could pose a solution for the South African housing crisis.

This artificial reef structure made for Seaboost mimics natural coral reefs’ role of providing habitat and shelter for marine organisms. Artificial reefs offer some of the world’s most diverse ecosystems. They also offer several benefits to marine life and the surrounding environment, protecting our shorelines from erosion.

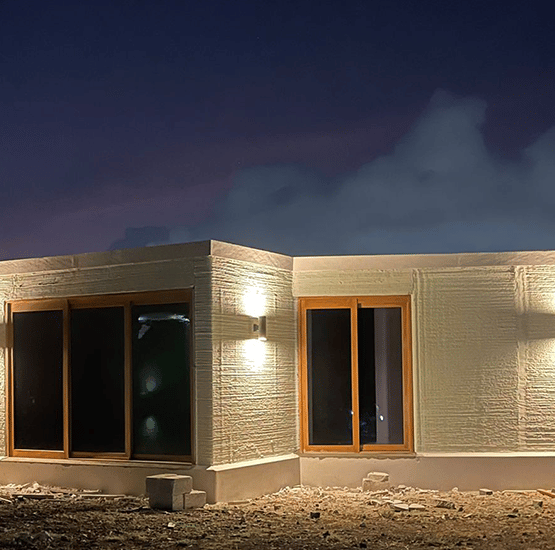

The Robust Villa is the first housing design built from the Lyve by Cybe label. This project used Lyve’s accessible and customizable platform to efficiently produce a home in five weeks and create a business case for the housing shortage crisis in Curaçao.

La Sphère is a free-standing guardhouse within a 180-unit social housing district. In addition to providing security to its residents, the construction of the building used one-third less concrete than traditional methods.

The Sapporo Park Restrooms are functioning toilet prototypes designed and printed in Japan. The intention of the structures is to create simple sanitation solutions for countries that lack such appropriate facilities.

The MEET Villa is a multi-sector collaboration that celebrates culture and innovation. 3D printed and powered by solar energy, the MEET Villa combines modern technologies with Emirati heritage.

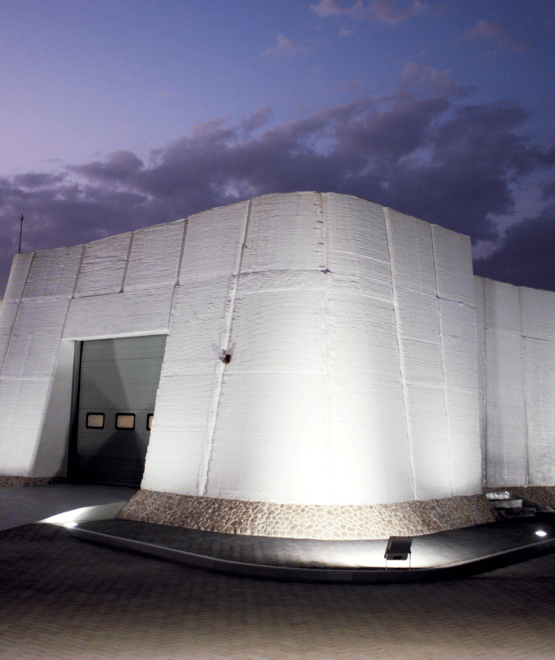

Translating to “The Meeting Factory” in English, De Vergaderfabriek’s iconic and dynamic design is built to inspire team collaboration. Printed in 10 days and with reduced emissions and waste, it is efficiently and sustainably produced.

The 3D Studio 2030 is an 80-square-meter house built to inspire and encourage new and efficient building techniques in Saudi Arabia. It illustrates the potential for creating affordable housing with 3D concrete printing.

The 3D Housing 05 is a prototype home that was constructed and exhibited during the Milan 2018 design week. It was created to demonstrate the potential for new sustainable and affordable housing solutions using 3D printing technologies.

Located in Dubai, the R&Drone Laboratory is the world’s first 3D concrete printed laboratory. The construction houses a research center for drone and 3D printing technologies.

At CyBe Construction, we believe that collaboration breeds innovation. We’re proud to work with communities and companies from around the globe — and to use those experiences to further cultivate our industry knowledge.