CyBe Construction redefines construction by enabling 3D Concrete Printing for all clients throughout the industry. We provide hardware – 3D printers – software and material to simplify the complex building processes.

CyBe Construction is an ambitious, award-winning tech company, established in 2013. We redefine construction by enabling 3D Concrete Printing for all clients throughout the industry. We provide hardware, software and material to simplify the complex building processes. We guide the industry through education, certification and business development.

CyBe Construction redefines construction by enabling 3D Concrete Printing for all clients throughout the industry. We provide hardware – 3D printers – software and material to simplify the complex building processes.

We strongly believe that one integrated system combining hardware, software and material is key. As a result, we have co-developed CyBe MORTAR specifically for the application of 3D concrete printing.

An aligned combination of hardware and software results in an integrated system, which enables partners to develop their own material.

In addition to offering hardware, software and materials, we also offer a learning platform. Depending on where your interest lies, or what you want to learn, you can scroll through our various courses covering a wide range of aspects of 3D concrete printing.

At CyBe Construction, we provide solutions for affordable housing to the construction industry. What started as a fascination of building and innovation has grown to an independent company providing solutions for building projects quicker, cheaper and more sustainable.

The construction industry benefits greatly from 3D concrete printing technology for building affordable housing, as it is a means to an end during the current global housing shortage.

We provide the hardware, software and material to simplify the complex building processes. But also we guide our customers through the route towards affordable housing through education, certification and business development.

Thanks to short cycle times, rapid changeovers, and consistent precision, our 3D printing technology is the perfect answer to your building challenge.

If you are a future-focused company in the construction industry, you’ve probably heard something about 3D concrete printing. It’s an efficient method of building that minimizes materials and labor costs and maximizes production.

On top of that, it can also pave the way for a construction sector with more sustainability by incorporating more clever designs and optimized use of materials. Particularly in a housing shortage period, 3D concrete printing machines bring incredible value to the construction industry.

3D concrete printing machines create structures layer-by-layer based on programmed input. CyBe’s printers use CyBe’s Chysel and Artysan software , which prepare 3D models for the machine and control the printing. The input from the software guides the machine, which positions itself and its nozzle in the correct location at the correct time. The mix-pump system moves CyBe Mortar through a concrete pump hose to the robotic arm, while the machine constantly moves from coordinate to coordinate while extruding a steady stream of concrete.

Depending on the size of the structure, concrete mortars with varying set-times are used. For wall elements, a fast-drying mortar is ideal. CyBe’s specially developed, fast-drying CyBe Mortar sets in 3–5 minutes. One wall element can be printed within 1–2 hours. This makes it possible to print all the walls of one of our Lyve Design within 2 to 3 days. After 24 hours of hardening, elements can be hoisted and placed at their final location. For printing entire finished modules, a longer set-time is necessary to achieve wet-on-wet connection. Depending on the exact size of the print area, CyBe Mortar Gantry will set within 15–40 minutes.

We strongly believe that one integrated system combining hardware, software and material is key in achieving the best results for 3D concrete printing for several purposes.

Wall elements – Within our Lyve concept our team of designers and architects has developed various designs that are easy to build using the various 3D concrete printing technologies. The method of printing with the CyBe Robotic-line (R-line) printers is done by dividing the design into wall elements. All these wall elements can be printed within 2 to 3 days. After this the next phases of the construction can immediately be done; e.g. roof and water- & air- tightening of the building, placement of doors & windows, the installation of mechanical & electrical services and public sanitation & hygiene facilities.

CyBe’s principle is to optimize any design to the local regulations, requirements and expectations. As a result it is possible to optimize any concept in insulation, wall thickness, structural principle and local special requirements such as earthquake regulations.

Modular construction – Our patented concept of Prefabricated Prefinished Volumetric Construction (PPVC) is a construction method we have developed for our CyBe Gantry-line (G-line) printers. This concept consists of free-standing 3-dimensional modules that are completed with internal finishes, fixtures and fittings in an off-site fabrication facility, before it is delivered and installed on-site. We created a living solution that helps you and your environment, as this way of construction we can cut down the cost of gas, water and light to a minimum.

Artificial reef – Our range is not limited to 3D printing technology for building houses only, as our machines serve various markets such as coral reef restoration; An incredible solution for our oceans’ main problems. Artificial reefs can produce rapid increases in the growth of algae, coral, and local fish populations. Our material has shown great results of containing certain elements like coral, because of the roughness of the material.

Manholes – The use of the 3D concrete printing technology for the production of manholes has many benefits. For example, the production time of 3D concrete printed manholes is a lot quicker than traditional because of the fast curing time of the CyBe Mortar. The manholes can be measured by the printing equipment, shared with the printing software and printed within 1 to 2 hours. As a result, this will minimize the required materials and labor costs and will maximize the production.

Street furniture – The concrete 3D printing technology enables us to offer a variety of efficient, quick, sustainable and affordable solutions for not only construction projects, but also landscaping projects. Both applications can be done with the same 3D concrete printing technology.

Art – Another benefit of the 3D concrete printing technology is the design freedom, which makes it also perfectly suitable to create art and abstract design without the need for costly molds.

Speed is key – With our 3D concrete printing technology, we can build housing projects five times faster than conventional construction. The combination of our 3D concrete printers with the CyBe Mortar allows us to print the wall elements of our Lyve designs within 2 to 3 days. After 24 hours, the printed elements can be hoisted and the building can be finalized.

More sustainable – Due to the precision of our 3D concrete printing technology, the machine only applies the mortar where it’s needed. This means that less material is needed, less waste is produced and therefore less CO2 is emitted. On top of that, the production of our eco-frienly material, CyBe Mortar, emits up to 32% less CO2 than Portland cement.

Freedom of form – In conventional construction, the formwork determines the shape of concrete when pouring the concrete. 3D concrete printing technology opens up the ability to build complex designs that are otherwise not possible, or too expensive or labor-intensive to create by conventional construction methods..

The first step towards your own 3D concrete printing technology would be to determine the print application that you will be using:

The next step would be to have a call to dive deeper into your application, give you an overview of the solutions we offer, answer any questions you may have, and discuss the way forward.

Subsequently, the following step would be to purchase the 3D concrete printing technology and together set up the local production of the CyBe Mortar.

After 6 to 9 months, the CyBe 3D printer will be ready for shipment and your future operators will be trained during a 10-day training course by the CyBe Team. To support a continuous learning curve, we also provide online education on our Lybrary to teach your team everything about all aspects of 3D concrete printing, from operational and design levels, all the way up to strategic and tactical levels.

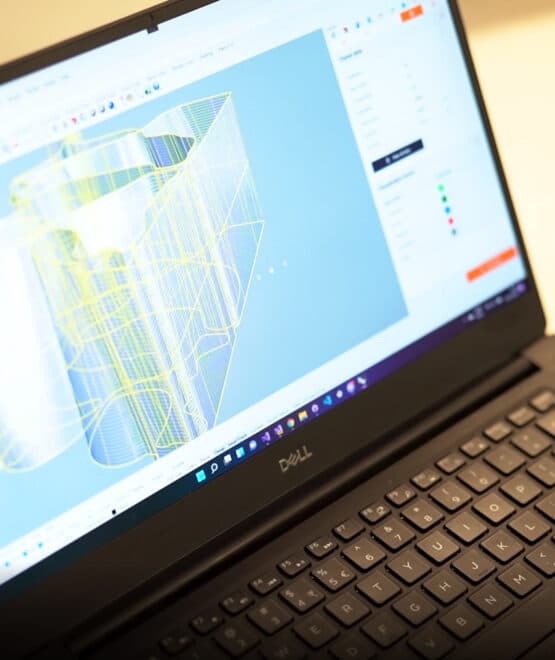

Our 3D printing technology is standardly provided with CyBe Chysel software. Chysel is the ‘slicing’ software used to generate a toolpath from digital 3D models. Within Chysel, you have access to variables relevant for your personalized printing strategy. Some examples of what can be given as input are layer width, layer height and the printing speed.

It keeps track of already printed objects and ensures that the 3D printer will not collide with these objects.

Based on the generated toolpath code by Chysel, CyBe Artysan software is used to control the machine and keep track of the 3D print statistics such as printing time, humidity, outside temperature, temperature of the material, rotor stator temperature and the values of the additive during the start-up and printing procedure.

A significant amount of time can be saved during the design phase of a building project by employing parametric design.

Unlike traditional design methods, parametric design allows different components to be easily adjusted. These design components, referred to as parameters or variables, can contain items such as the number of rooms or the positioning of doors and windows. For example, the number of rooms in a building (as one parameter within a design) can be changed, and the other parameters that relate to it (e.g. positioning of doors and windows) will be automatically adjusted to correspond. The parametric design software easily modifies the overall design while calculating the relationships between the various components. It can take a lot of time and effort to manually modify each design element, therefore parametric design is an efficient way of cutting down time and costs on the designing for affordable housing.