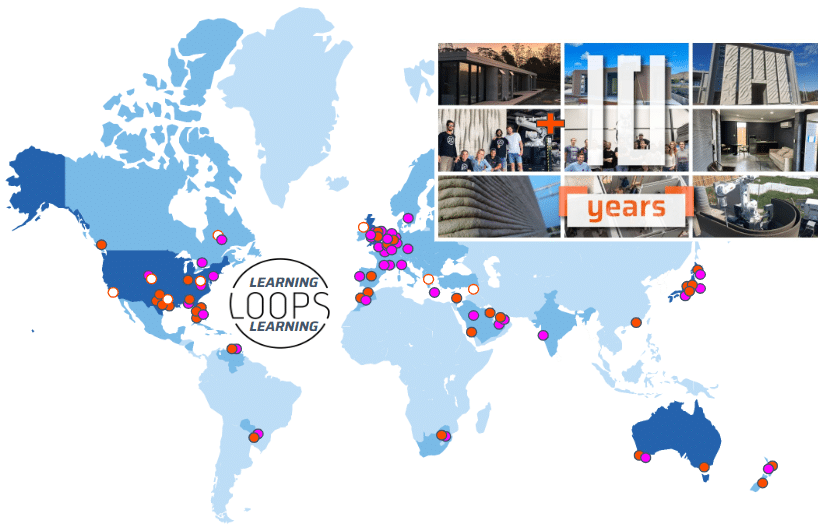

over 10 Years of Sustainable Impact through Building Automation

At CyBe Construction, we understand the structure and fragmentation of the AEC Industry, resulting in various Challenges for the Local and Global Societies. With over a decade of experiences in Building Automation via 3Dprinting & Parametric design, and over 35 years of experiences and skills in Construction based on century of Construction information and experiences from former Generations, we also know how these Challenges can be Changed into Opportunities. It’s time for a new system, a new Building System. It’s time for the new Generation of Building, the Generation of Innovative Building. We Built the CyBeDC (CBDC) !

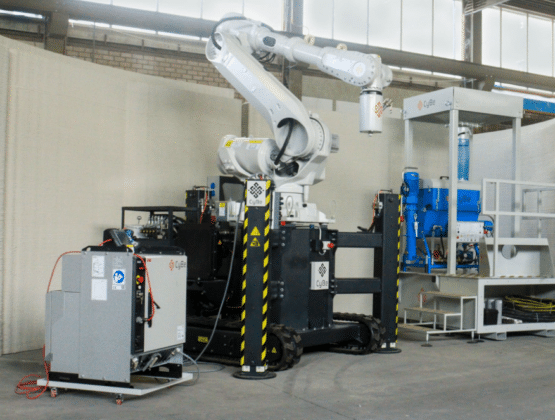

We deliver 3Dprinters

CyBe offers 3Dprint systems including the Hardware and Software that simplify traditional Construction processes. We developed the R line and G line based on economy or premium class 3Dprint system with a variety of options to Automate the Building process.

3D YNK

Since the start of CyBe Construction the team focussed first – in close collaboration with KORODUR – on the development of the 3Dprintable material, resulting in the CyBe MORTAR. Due to further developments the CyBe MORTAR resulted in a material system family – 3D YNK – of 3Dprintble materials. This could either be the full Mixture or Compound used in various applications and with related 3Dprint systems such as the RC 3Dp and GR 3Dp.

Building Applications

The Prime Time of Your Life – so Lyve! What we do has Impact — with over 10 years of results. CyBe focus is on Impactfull applications – enabling Living (LyVe) – with Impact and providing transparent insight into what the technological eco systems we provide can do around the world with comprehensive summaries of each project.

We are Many l CyBe Digital Collective

Via the CyBeDC “We are Many” I We, via BRAYN, are Collective and connecting Global partners, providing essential information and comprehensive experiences about 3Dprinting in Building that includes design and engineering references, 3Dprinting data, project management tools covering GROTICK principles, and Training and Education courses to become BaaS or BRAYN certified.

At CyBe Construction, we believe that

collaboration breeds innovation. We’re

proud to work with communities and

companies from around the globe —

and to use those experiences to further

cultivate our industry knowledge.