CyBe Construction offers 3D concrete printing (3DCP) services for clients in every facet of the construction industry — and all over the world. CyBe hardware, software, and learning materials simplify the usually complex building process, making additive manufacturing accessible for everyone. Thanks to short cycle times, rapid changeovers, and consistent precision, our 3D concrete printers are the perfect answer to your building challenge. On this page, you’ll find out about the 3D concrete printing prices, and how to buy a 3D concrete printer. Want to know how to choose the best printer for your company?

Learn more

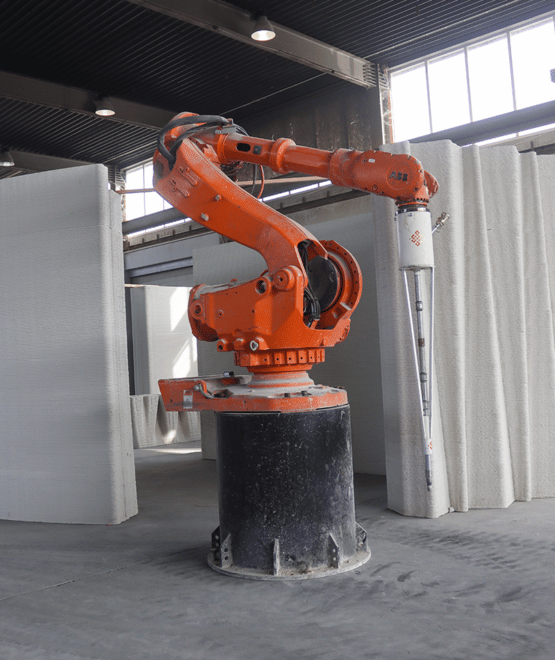

CyBe R (Robot)

Our CyBe R (Robot) is an entry-level fixed 3D concrete printer. This printer is ideal for research institutes, universities, and suppliers performing in-house testing, prototyping, or precast production. The ABB robotic arm is attached on a metal frame which is secured to the floor.

The mix-pump system moves CyBe mortar through a concrete pump hose to the robotic arm, which then 3D prints in the programmed location. The robot itself is controlled via a control unit that runs CyBe software.

What you get:

- Robotic arm and printhead

- Robot base

- Control unit (including CyBe software)

- Mix-pump system

- Starter kit

- Training for four print operators

Delivery:

- We deliver 3Dprinters in a time of approx. 4 months after receiving first payment. Ask about options for machines in stock to reduce delivery time.

*Price ex works, based on standard dimensions, only while supply lasts!

CyBe RC (Robot Crawler)

Our CyBe RC (Robot Crawler) is a mobile 3D concrete printer and can be used in multiple locations. Thanks to its portability, this printer is ideal for construction companies printing on site. It can also be used in precast factories. The ABB robotic arm is attached on a movable crawler with rubber tracks that make it easy to maneuver the printer regardless of the terrain. The hydraulic feet stabilize the machine while it prints and are extendable, increasing the total printable height of projects.

The mix-pump system moves CyBe mortar through a concrete pump hose to the robotic arm, which then 3D prints in the programmed location. The robot itself is controlled via a control unit that runs CyBe software.

What you get:

- Robotic arm and printhead

- Crawler system

- Control unit (including CyBe software)

- Mix-pump system

- Starter kit

- Training for four print operators

Delivery:

- We deliver 3Dprinters in a time of approx. 4 months after receiving first payment. Ask about options for machines in stock to reduce delivery time.

*Price ex works, based on standard dimensions

CyBe RT (Robot Track)

Our CyBe RT (Robot Track) is a 3D printer with an ABB robotic arm that moves across a stationary track setup. With a track length starting from 5 meters, the reach of the 3D printer extends accordingly. Track segments can be added incrementally. The Robot Track can be used by precast factories building prefab homes. It is also great for institutes or companies that want to print in a sequence and test design variables.

The mix-pump system moves CyBe mortar through a concrete pump hose to the robotic arm, which then 3D prints in the programmed location. The robot itself is controlled via a control unit that runs CyBe software.

What you get:

- Robotic arm and printhead

- Track setup

- Control unit (including CyBe software)

- Mix-pump system

- Starter kit

- Training for four print operators

Delivery:

- We deliver 3D printers in a time of approximately 4-6 months after receiving first payment. Ask about options for machines in stock to reduce delivery time.

*Price ex works, based on standard dimensions

CyBe GR (Gantry Robot)

Recognized as one of the most advanced 3D concrete printers in the world, our CyBe G (Gantry) can print anywhere within an established three-dimensional zone. The Gantry Robot is a stable setup of six columns and three beams. It is best suited for printing large modules, such as finished apartments, in a factory setting. It is ideal for construction companies who are interested in building affordable housing. The Gantry Robot has an ABB robotic arm attached to it, to ensure the most precise prints

CyBe mortar offers the ideal set-time for wet-on-wet printing in large print areas. The mix-pump system moves CyBe mortar gantry through a concrete pump hose to the printhead, which then 3D prints in the programmed location. The Gantry Robot is controlled via a control unit that runs CyBe Software.

What you get:

- Robotic arm and printhead

- X-Y-Z columns and beams

- Control unit (including CyBe software)

- Mix-pump system

- Starter kit

- Training for four print operators

Delivery:

- 6–9 months after official purchase (depending on options)

*Price ex works, based on standard dimensions

Stay Ahead of the Game with Financial Leasing for 3D Concrete Printers

If you are a business looking to acquire a 3D concrete printer, financial leasing may be the solution you need. This option offers several advantages, including cost-effectiveness, access to modern technology, and flexibility.

One of the primary benefits of financial leasing is that it is a cost-effective way to acquire a 3D concrete printer. Rather than paying the full purchase price upfront, businesses can make fixed payments over time. This can help conserve cash and free up capital for other business needs. By choosing leasing, you can enjoy the benefits of owning the equipment without having to bear the full cost of ownership.

Access to modern technology is another advantage of financial leasing. A 3D concrete printer can offer significant advantages in terms of efficiency and quality, allowing businesses to stay ahead of the competition. Leasing the equipment rather than purchasing it outright allows businesses to gain access to the latest technology without having to commit significant amounts of cash upfront. This can help businesses stay competitive and improve their output without compromising their financial situation.

Flexibility is also a key benefit of financial leasing for a 3D concrete printer. Leasing companies offer payment structures and buyout options that can be tailored to meet a business’s specific needs and circumstances. This can be particularly useful in industries that are subject to fluctuations in demand or other external factors. With flexible leasing arrangements, businesses can make the most of their equipment and adapt to changing market conditions.

Service and support of our 3D concrete printers

We take pride in our reliability, flexibility, and efficiency — when it comes to ourselves and our machines. We use our experience and expertise to create innovative yet easy-to-use technologies as well as solve challenges remotely or onsite. Choose from annual maintenance and inspections, spare part support, virtual support, and more with a service level agreement.

3D house printer: the future of living

Based on practical experience in 3DCP, our architects and structural engineers work to advise and assess projects. Our range of action varies from designing new 3D concepts and doing structural calculations to assessing external designs in order to “make it printable”. This integral approach goes further than just the printed parts; it expands to the entire construction process. We study how components such as floors, windows, partitions, etc., interact with the printed elements and provide a holistic model on how this technology can make a building more sustainable, efficient, affordable, and along a faster construction process. For us, the D&E phase is the part of the process where everything has to be align in order to get the final result because with a digital twin we will 3Dprint later. The level of detail and planning is stronger in this part of the process compared to traditional construction. We provide these services to make 3DCP easier for our clients so they can focus on production. Our Design & Engineering (D&E) efforts focus on three phases with following deliverables:

Conceptual phase:

- Design guidelines for 3DCP, which will be the basis for the conceptual design.

- 3DCP analysis of the entire conceptual design.

- Recommendations on the design in order to make it printable.

- Preliminary segmentation and element anatomy.

Technical phase:

- Final segmentation and element anatomy.

- Digital 3D model of the printed elements.

- 2D principle details of crucial connections between the 3D printed elements and conventional elements.

Operational planning phase:

- 3D Concrete Printing element overview.

- Construction site logistics, facilities and 3D printing sequence.

- Set reference points for the to-be-printed elements and for the 3D concrete printer positioning based on floor plan.

- Overall conceptual building schedule.

- Cost indication for 3DCP works within construction phases.

Interested in buying one of our printers? Request a quote or click one of the printers for more information.

- How does 3DCP work?We receive a 3D-model which can be made with one of the many CAD tools. With the help of our own software-tool (CyBe CHYSEL) we are able to convert a digital 3D model into the printing instructions (the .Gcode) needed for the 3Dprinters. The printer is operated by just two persons; one uses a control unit to calibrate the right position. The other operator oversees the mixing part that mixes the CyBe MORTAR which is used as the material for the printer. After the print has started everything goes automatically. During this time we wait till the print is done and give ourselves the opportunity to get a cup of coffee.

- Is it possible to distribute your products to my country and what are the terms of delivery?We distribute our products worldwide. The printers are modular, which means they can be separated in smaller parts for transport easily. Additional costs such as transportation and import taxes will be added to the printer and are the buyer’s responsibility. The terms of delivery also depend on the location to which the product needs to be transported.

- What are the advantages of 3DCP in comparison to traditional construction methods?Traditional construction processes take up a lot of time and labor costs. Due to engineering and preparation time the construction takes a longer time span than 3DCP. Since we are able to automatize this process the time preparing a print is reduced a lot. The final costs of 3D concrete printer are reduced too. This can be up to -70% depending on the product you want to print. This cost-reduction is the result of factors like low labor costs and material costs. In addition 3Dconcrete printing enables new and other design possibilities. Giving architects more freedom in their design. Still there are many new design and engineering possibilities not yet being discovered and since the technology is being further developed new possibilities will occur.

- I am interested in purchasing a 3D printer, how do I get in touch?We are happy to provide you with the specifications! Please fill in our contact form