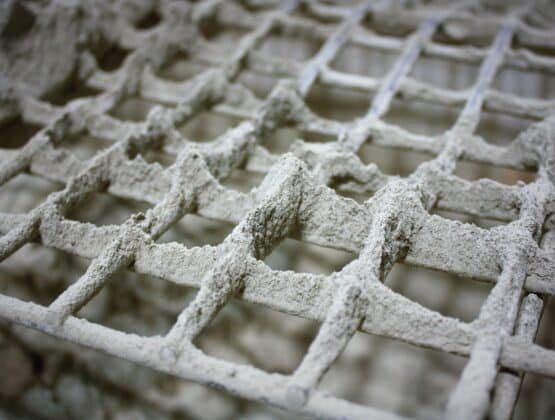

From our point of view, we strongly believe that one integrated system combining hardware, software and material is key. As a result, we have co-developed CyBe Mortar specifically for the application of 3D concrete printing.

CyBe Mortar

CyBe Mortar can be used for architectural, structural, industrial, and design projects regarding 3D concrete printing applications. It is a high-performance, single purpose material and durable in all environments. Besides, it is non-metallic, and contains very low amounts of chloride and sulphate. The material was specifically designed for 3DCP, in a material development collaboration together with our partner Korodur.

Use CyBe Mortar with our 3D concrete print technology to produce high durability objects where low shrinkage is desired. Our material sets in three minutes and achieves structural strength in only one hour. This allows a fast and efficient printing process, a reduction of costs and sustainable results.

3D Concrete Printing with CyBe Mortar

CyBe Mortar enables to 3D print at speeds of max. 600 mm/s and layer heights from 10mm up to 50 mm. Moreover, the time-window to print on top of a 3D printed layer only takes five seconds.

Applications

Use CyBe Mortar with 3D concrete printing for architectural, structural, industrial and design purposes.

Environmental advantages

Use our material to reduce your carbon footprint and lower your environmental impact. Production of CyBe Mortar emits up to 32% less CO2 than portland cement, and the mortar can be used as an eco-friendly building material.

CyBe Mortar Highlights

3Dprintable

Specially developed for 3D concrete printing applications.

Durable

Formulated for long life even in critical applications.

Structural

For structural and non structural construction components and objects.

Singlepurpose

Usage only for 3D concrete printing with 3D concrete printers analysed and approved by CyBe Construction.

Local production

We understand that shipping materials all over the world is costly and time consuming. Therefore it is possible – within a partnership – to produce CyBe Mortar locally. We send our so-called ‘CyBe Power Pack’, which can be mixed with local aggregates. This helps the environment, and your wallet!

Material for 3D Concrete Printing

- What kind of material is used for 3d concrete printing?Though the construction method is commonly known as 3D concrete printing, the used material isn’t exactly concrete. For 3D printing: we use mortar; specifically our in-house developed CyBe Mortar

- What does 3D concrete printing material consist of?To print, we use mortar: a mixture that often includes additives like cement, sand, and water. Blending these materials creates a paste-like consistency, which can be printed.

- What 3D concrete printing material does CyBe use for their systems?We recommend utilizing CyBe Mortar, a material rigorously tested and certified for its rapid set-time. Our CyBe Mortar Ready-Mix facilitates high-speed, high-quality printing. Through our cutting-edge technology and intelligent printing processes, we achieve a print width of 40 mm, significantly reducing the required material volume. Additionally, through our Partnership Program, CyBe Mortar can be produced locally by blending our concentrated CyBe PowerPack with regionally available resources such as cement, aggregates, and sand. It’s essential to note that our systems are specifically optimized for use with our proprietary material. However, clients retain the flexibility to use alternative materials if desired. Over our 10 years of printing, we have worked with a multitude of materials available around the globe. While we have yet to find a better printing material than our own CyBe Mortar, our equipment is capable of processing and printing with a wide variety of other materials as well.

- How can I optimize material costs in 3D concrete printing?Our standard print layer width is 40 mm, which effectively minimizes material usage compared to traditional concrete walls or other 3D concrete printers. This inherently reduces the amount of material required. Additionally, through our Local Material Development Program, we empower our customers to produce CyBe Mortar locally by blending our concentrated CyBe PowerPack with regionally available materials such as cement, aggregates, and sand. This initiative not only reduces raw material expenses and transportation costs but also ensures the quality of the material, leading to optimal printing results.

- Can I mix and use my own material with your 3D concrete printer?Yes, you have the option to mix and use your own developed material with our system. However, it is important to note that doing so carries certain risks. We cannot guarantee the system’s proper response and functionality, as it may be susceptible to issues such as clogging. Furthermore, we cannot assure that the material will yield the same high-quality print results as CyBe Mortar. It is essential to understand that using your own material will void the system’s warranty.

- What are the technical specifications of 3D concrete printer material CyBe Mortar, such as strength and curing time?The technical specifications of CyBe Mortar include superior strength compared to traditional concrete. The mortars exhibit fast curing times, typically ranging from 3 to 25 minutes, depending on the specific type of mortar and the length of the print path. For wall elements printed with the CyBe Robot Crawler, a three-minute set time is optimal. The curing time of the mortar can be adjusted by varying the amount of retarder added to the mix. For a comprehensive overview of the mortar’s technical specifications, please refer to the CyBe Mortar datasheet available in our Knowledgebase in the CyBe Lybrary. You can find the link to our CyBe Lybrary at the top of your screen.