A strategic approach to affordable housing

If you’re new to 3D concrete printing technology, you may be wondering if an investment in a 3D concrete printer is right for your company. How does this type construction work and what are its benefits?

One of the major benefits is the speed at which homes can be built. It is the solution to fast home building and has the potential to be the solution to the housing shortage as well.

The market needs affordable housing and 3D concrete printing’s efficiency helps deliver on this while creating positive cash flow. By creating a business case and an efficiency-focused strategy, your company can achieve maximum profit. In this basic overview, you’ll understand how it differs from traditional construction and how to factor a return on your investment.

Breaking down and adding up construction costs

There are some similarities between traditional building and 3D concrete printing, but there are also many differences that makes it much more cost effective. In both cases, there will always be an accumulation of direct and indirect costs.

Direct costs

Direct costs are costs that are directly related to the components of the construction project. This includes:

- Materials

- Labor

- Equipment

- Any necessary subcontracting

Calculating the total direct costs is done by itemizing each material and activity of the construction process. The costs of materials and labor is added with the cost of equipment and any necessary subcontracting.

Indirect costs and total building costs

Indirect costs are costs that are directly related to the construction project, but not to the components. When forecasting construction costs, indirect costs are represented as percentages of the total direct costs.

Indirect costs include:

- General construction site costs — 15% of total direct costs

- Overhead costs — 6% of total direct costs

- Risk and Profit — 3% of total direct costs

- Insurance — 0.35% of total direct costs

When we add the total direct costs with each of the indirect costs, we arrive at the total building costs.

D = direct costs

D + (0.15*D) + (0.06b*D) + (0.03*D) + (0.0035*D) = Total building costs

Every subcontractor involved in the construction project will make the same calculation for their area of development. In other words, every subcontractor will multiply their direct costs by the four indirect costs. The subcontractors of each subcontractor will do the same as well.

It’s easy to see how subcontracting costs can quickly add up. Cutting subcontractors from the project can save a lot of money — and 3D printing helps to streamline aspects of the construction process, helping to reduce some of this cost.

Cost savings compared to traditional building

3D concrete printing technology decreases the direct and indirect costs of a construction project. The most significant savings are related to the indirect costs and require a strategy of efficiency and a matching business case.

Direct cost savings

The printing process is one part of a total construction project. There are many steps and elements of the construction process that are the same as traditional building, for example, installing window and door frames. These costs will be the same for each.

Some components or steps of traditional construction are unnecessary when building with 3D concrete printing. These are:

- Formwork

- External walls

- Plastering

- Utilities installation preparation

- Subcontracting for these steps

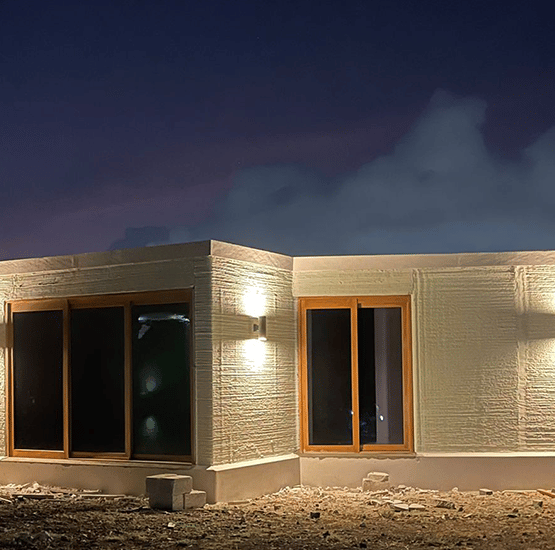

Eliminating these steps affects the direct costs. As an example, the Robust Villa, a 104m2 home 3D printed in Curaçao, resulted in a 2% direct cost savings, when compared to traditional construction. However, this only represents a portion of the potential cost savings.

Indirect cost savings

As discussed earlier, direct costs are multiplied by the four indirect building costs, represented by percentages of the total direct building costs.

But the inherent nature of 3D concrete printing allows individual buildings or modules to be built faster and in continuous succession. This optimizes the printing process, speeds up the construction process, and saves money. This quick and efficient approach to building is ideal for affordable housing.

Whether printing on-site with the CyBe RC Robot Crawler mobile printer or off-site with the CyBe G Gantry setup, 3D printed buildings can be completed from site preparation to finishing in five weeks — five times faster than traditional construction.

Working five times faster means that the general construction site costs are reduced from 15% to 3%.

Using the example of the Robust Villa printed in Curaçao, the 2% direct cost savings is added to the savings in general construction site costs. For the Robust Villa, this combination resulted in slightly less than 15% in total building cost savings.

Optimizing Return on Investment

When planning for optimum Return on Investment (ROI), time is the most valuable factor. To get the most potential and profit from 3D concrete printing, an efficient construction strategy must be used. A good strategy results in a faster ROI and a more positive cash flow because projects can be delivered sooner.

The 5-week construction loops shown above help to achieve the best Overall Equipment Effectiveness (OEE). Reducing the construction timeline of one house from 25 to 5 weeks means that five times more buildings can be constructed in those same 25 weeks — that’s 500% more potential profit over 25 weeks.

After creating a printing strategy and determining the potential profit, it is easy to calculate your ROI. Your specific ROI will depend on your business strategy and which CyBe printer your company purchases. There are different CyBe printers built to satisfy different building strategies.

As an example, the Robust Villa was printed with the CyBe RC mobile printer, which sells for €195,000 Ex Works. In the example above, constructing five buildings in 25 weeks would yield a profit of approximately €7500. After building 26 such projects, the cost of the investment would be met, and your company could begin building profit. You can also download a more detailed cost indication for the Robust Villa